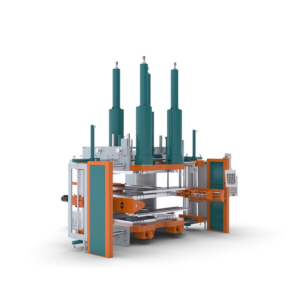

At Dekuma, we have been committed to developing high-quality solutions in the rubber processing industry for decades. Since our establishment in 2004, we have focused on providing technologically advanced equipment tailored to the unique needs of our clients. Among our most trusted offerings is the rubber vulcanization machine, which has proven highly effective across specialized sectors such as insulator production and rubber track manufacturing. By integrating precision engineering with robust design, we ensure that our machines consistently deliver reliable and efficient performance in demanding applications.

Enhancing Insulator Production with Advanced Equipment

We understand that the production of rubber insulators requires precise control over vulcanization parameters to maintain high-quality output. Our rubber vulcanization machine is specifically designed to handle these requirements, offering uniform heat distribution and accurate pressure control throughout the vulcanization process. By leveraging our in-house technology, we can provide equipment capable of meeting the stringent quality standards of electrical and power industries. We have observed that clients using our systems achieve reduced material waste, improved product consistency, and greater operational efficiency, which are critical factors in competitive manufacturing environments.

Optimizing Rubber Track Manufacturing

In addition to insulators, our expertise extends to the manufacturing of rubber tracks for engineering and agricultural vehicles. The rubber vulcanizer machine we provide is engineered to accommodate large, complex molds while maintaining precise temperature and pressure control. This capability ensures the finished tracks exhibit optimal elasticity, durability, and strength. We have consistently worked with clients in the construction and agricultural machinery sectors, refining our solutions to adapt to specific material formulations and production requirements. By doing so, we empower our clients to produce high-quality tracks that meet global standards while reducing downtime and production costs.

Commitment to Innovation and Client-Centered Service

At Dekuma, we are dedicated to providing comprehensive rubber vulcanization solutions that cater to both standard and niche markets. All core components of our machines are designed by our experienced technical team, and raw materials are meticulously selected to guarantee durability and production stability. Our focus on innovation allows us to develop customized equipment for specialized applications, ensuring clients receive a solution perfectly aligned with their manufacturing objectives. By integrating feedback from industry experts and continuously improving our technology, we remain at the forefront of specialized rubber equipment development.

Conclusion: Reliable Solutions for Niche Applications

In conclusion, our mission at Dekuma is to combine technological innovation with practical expertise to create value for our clients. Whether it is the precise production of insulators or the robust manufacturing of rubber tracks, our rubber vulcanizer machines consistently provide reliable, high-quality performance. We continue to advance our solutions to meet the evolving needs of the rubber processing industry, ensuring that our clients achieve superior results with every production cycle. By choosing Dekuma, manufacturers gain access to equipment that not only enhances productivity but also supports long-term growth in specialized rubber sectors.