At Dekuma, we have always focused on delivering advanced solutions for rubber injection molding that meet the diverse needs of our clients. Since our establishment in 2004, we have developed and refined our expertise in producing high-quality machinery for industries ranging from automotive to military vehicles. Our commitment to innovation and precise engineering allows us to offer equipment that excels in both performance and reliability. Among our notable offerings, the customized rubber molding machine has proven essential for clients requiring tailored solutions in specialized sectors, such as insulator production and rubber track manufacturing.

Precision Engineering for Niche Applications

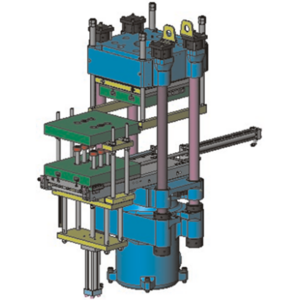

Our custom molding machine is designed with industry-specific challenges in mind. We understand that standard machines often fall short when producing components with unique geometries or specialized material requirements. By integrating core components developed in-house and selecting raw materials according to strict technical standards, we ensure that our equipment delivers consistent quality and operational stability. Clients in the electrical and construction machinery industries, for instance, benefit from machines capable of producing high-precision insulators efficiently, minimizing waste and ensuring long-term reliability.

Tailored Solutions Through Custom Mold Machining

One of the key advantages we provide is our expertise in custom mold machining. By offering fully tailored mold solutions, we enable manufacturers to produce complex rubber parts, such as heavy-duty tracks for agricultural or engineering vehicles, without compromising structural integrity or material properties. Our technical team collaborates closely with clients to understand their specific requirements, from material selection to mold design, ensuring that every machine is optimized for maximum performance in its intended application. This hands-on approach distinguishes us in the field of specialized rubber equipment and positions our products as a practical alternative to our competitors’ machinery.

Commitment to Continuous Improvement

We believe that innovation goes beyond machinery; it extends to service and support. Our team at Dekuma provides comprehensive guidance throughout the lifecycle of each customized rubber molding machine, ensuring that operators can achieve the best results with minimal downtime. We continuously gather feedback from clients in niche industries to refine our designs and enhance machine capabilities. Whether it is improving the precision of insulator production or increasing the efficiency of rubber track manufacturing, our solutions are built to meet evolving market demands while maintaining consistent quality standards.

Conclusion

By focusing on industry-specific applications and leveraging our expertise in custom molding machine design and custom mold machining, we at Dekuma are committed to empowering manufacturers with reliable, high-performance rubber molding solutions. Our dedication to precision, innovation, and client collaboration enables us to deliver equipment that excels in specialized sectors, supporting the growth of both domestic and global industries.