Rubber molding is a critical process for manufacturers in a wide range of industries. Understanding the various molding techniques available is essential for ensuring the quality and precision of rubber parts. At Dekuma, we specialize in creating custom solutions for customers in need of rubber molded products. As one of the prominent custom rubber manufacturers, our goal is to offer a variety of rubber molding methods that meet diverse needs, whether for small-scale prototypes or high-volume production. Let’s explore the main types of rubber molding and how they benefit your projects.

Compression Molding: Ideal for High-Volume Production

Compression molding is a well-known and widely used technique for producing rubber molded parts. This method involves placing a rubber compound into a heated mold, where it is compressed under pressure. Custom rubber manufacturers, like Dekuma, often recommend compression molding for large quantities of simple shapes or larger, thicker components. This process ensures excellent material flow and uniformity, providing parts with consistent quality and strength. It’s an efficient method that is particularly useful for producing rubber seals, gaskets, and automotive components. The flexibility of compression molding makes it suitable for various industries, ensuring a great fit for your needs.

Transfer Molding: Precision with Complex Designs

For more intricate rubber molded parts, transfer molding is a top choice. In this method, the rubber is preheated and transferred into the mold cavity using a plunger. This ensures high precision and excellent surface finish, which is particularly important for complex shapes and tight tolerances. Rubber molded products manufacturers like Dekuma rely on transfer molding for applications that require detailed components such as electrical connectors, and agricultural parts. The ability to mold thin-walled parts with intricate features makes transfer molding ideal for industries that demand precision.

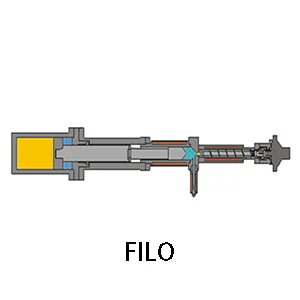

Injection Molding: Speed and Versatility for Diverse Applications

Injection molding stands out for its speed and versatility. This process involves injecting liquid rubber into a mold under high pressure, ensuring quick and uniform production. It is often used by custom rubber manufacturers like Dekuma for both small and large-scale productions, providing high-quality parts in less time. The technique allows for excellent control over material flow and part thickness, making it ideal for producing small to medium-sized parts with complex geometries. Whether you need parts for electronics, automotive, or industrial applications, injection molding offers the speed and reliability required to meet tight deadlines and ensure consistent output.

Conclusion

At Dekuma, we pride ourselves on providing tailored rubber molding solutions for diverse industries. Our custom rubber manufacturers team works closely with clients to understand your specific needs, offering comprehensive support from design to final product delivery. With cutting-edge machinery and a deep understanding of the rubber molding processes, we ensure that each part is produced to the highest quality standards. Whether you require rubber molded products manufacturers for low-volume, high-precision applications or large-scale production runs, Dekuma is equipped to deliver results that exceed expectations. Reach out to us today to discuss your rubber molding requirements!