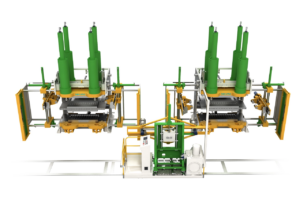

As industries strive to meet the demands of modern production, we at Dekuma have positioned ourselves at the forefront of innovation with our rubber vulcanizing machines. These machines are designed to optimize the production of rubber tracks, catering to industries such as agriculture, construction, and military applications. With our high-performance solutions, companies can enhance their production capabilities and meet strict quality standards.

High Automation for Increased Efficiency

One of the standout features of Dekuma’s rubber vulcanizing machines is their advanced automation. These machines offer automatic rubber loading, demolding, and material retrieval, streamlining the entire production process. Compared to traditional machines, the automated systems reduce labor costs by up to 50%, making production more cost-effective.

By minimizing human intervention, Dekuma’s machines also reduce operational errors, boosting throughput and improving overall efficiency. These automated systems enable businesses to maintain high production volumes with minimal downtime, allowing them to meet growing market demands while controlling operational costs.

Superior Quality with Long-lasting Performance

Dekuma’s China vulcanized rubber molding machine factory is committed to delivering products that last. Equipped with precision mold-clamping units and a constant-tension steel cord system, our rubber vulcanizing machines produce rubber tracks with a 30-50% longer service life compared to conventional designs. This longer lifespan significantly reduces maintenance costs and the need for frequent replacements, making us an excellent long-term investment for businesses.

These machines are built for reliability, even in the most demanding environments. Whether for agricultural tracks that endure rough terrain, military tracks requiring extreme durability, or snowmobile tracks exposed to severe weather conditions, Dekuma’s machines ensure consistent performance and superior strength.

Smart Monitoring for Optimal Control

To further enhance production efficiency, we integrate our rubber vulcanizing machines with the cutting-edge iSee4.0 intelligent management cloud platform. This advanced system allows for real-time monitoring of key parameters, such as energy consumption, temperature, pressure, and clamping force, all from a remote location. With this feature, businesses can track the status of their machines and identify potential issues before they lead to costly downtime.

The iSee4.0 platform also ensures that the vulcanizing process is carried out with the utmost precision, minimizing defects and maintaining a high standard of quality across all production batches. By optimizing machine performance and providing actionable data, Dekuma helps businesses improve their production quality and reduce operational inefficiencies.

Conclusion

Dekuma‘s vulcanized rubber molding machine factory stands as a symbol of innovation, offering high-automation, durable products, and intelligent monitoring systems to streamline rubber track production. By investing in our rubber vulcanizing machines, businesses can enhance efficiency, reduce costs, and maintain superior quality, ensuring they stay ahead in a competitive market.