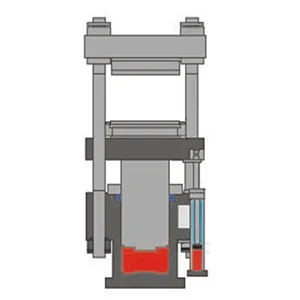

In the world of manufacturing, a standard solution often falls short. Unique products demand equipment that can adapt to specific materials, molds, and production goals. This is where the concept of a true custom rubber machine becomes critical. At Dekuma, we do not believe in a one-size-fits-all approach. Our philosophy is grounded in creating a custom molding machine that acts as a precise tool for your unique application, starting with the core of the process: the plasticizing and injection system.

German Engineering for Tailored Performance

The foundation of any reliable custom rubber machine is its ability to consistently prepare and inject material. Our plasticizing and injection units are optimized under the guidance of German technical consultants. This collaboration brings a methodical and precision-focused approach to the core mechanics of the machine. This external validation ensures that every Dekuma custom molding machine meets a high international standard of performance and reliability, providing a robust starting point for any bespoke production need.

Simplified Maintenance for Reduced Downtime

We design our systems with the operator in mind. A key feature that supports customization is serviceability. The screw in our unit is programmed to slow its speed before plasticizing ends, a subtle but important function that reduces wear on components. Furthermore, the injection piston is designed for easy disassembly. This focus on accessibility means maintenance and cleaning procedures are faster, which minimizes downtime when you need to change materials or perform routine upkeep on your custom molding machine.

Unmatched Process Control for Complex Parts

The true measure of a custom rubber machine is its level of control over the molding process. Our system provides three separate injection zones, each with independent pressure and speed adjustments, complemented by three dwell zones with the same level of control. This granular level of management is essential for handling sophisticated molds and challenging materials. It allows for precise manipulation of the flow front, ensuring complete cavity fill and optimal part density for even the most complex designs.

For manufacturers who require more than an off-the-shelf solution, Dekuma provides the technical foundation. Our investment in German engineering principles, combined with designs that prioritize ease of maintenance and unparalleled process control, results in a custom molding machine capable of supporting a wide array of specialized production requirements. We provide the tools that enable your specific vision to become a manufacturable reality.