In today’s competitive manufacturing landscape, choosing the right machinery can make a huge difference in the efficiency, precision, and overall output of production. For companies looking to produce custom rubber parts, a custom injection molding machine could be the key to unlocking enhanced performance. At Dekuma, we specialize in creating tailor-made machines that cater to the unique needs of our clients, offering improvements over standard models. But how exactly does a custom injection molding machine compare to traditional options? Let’s explore.

Flexibility in Design and Production Needs

One of the most significant differences between a custom injection molding machine and a standard model lies in their adaptability. With Dekuma’s custom machines, we can fine-tune every aspect of the molding process to meet specific production needs. For instance, we can customize the screw speed, injection pressure, and clamping force to suit your product’s unique requirements. This flexibility ensures that your machine can handle more complex molds and deliver consistent results, whereas standard machines are typically limited in their adjustments.

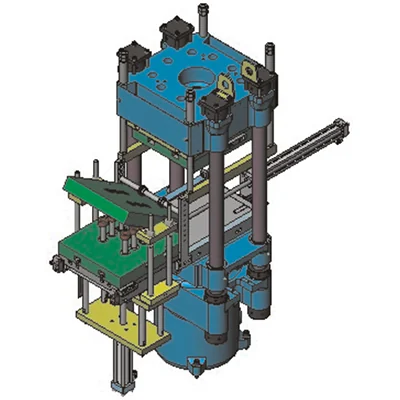

For instance, in Dekuma’s custom injection molding machines, we offer modular designs that allow for the easy inclusion of additional features such as multiple injection zones, precise pressure settings, and specialized cooling systems. This customization is crucial when dealing with materials that require highly specific temperature or pressure profiles. The ability to adjust these parameters leads to a much higher-quality output and optimized production efficiency.

Enhanced Control and Precision

When it comes to precision, Dekuma’s custom machines far exceed the capabilities of standard models. Our custom injection molding machines come equipped with advanced features, such as proportional flow valves and a dedicated temperature control system, ensuring smooth operation with precise control over all stages of the injection process. These features significantly reduce the likelihood of errors or material wastage, which is often seen with traditional molding machines.

Furthermore, the use of finite element stress analysis in the design of key components ensures that every part of the machine offers the right level of rigidity, allowing for more accurate and repeatable molding. The precise temperature regulation in Dekuma’s custom machines further guarantees that the molding process remains stable, even when handling complex rubber materials. The result? Faster cycle times and higher-quality molded parts with fewer defects.

Long-Term Durability and Reduced Maintenance

Another key advantage of a custom injection molding machine from Dekuma is its durability. Standard machines, while functional, often suffer from wear and tear over time, especially when subjected to complex or high-demand production schedules. Custom rubber manufacturers like Dekuma’s custom machines are designed with longevity in mind, incorporating premium components and advanced engineering techniques to ensure durability and extend the life of the equipment.

We also prioritize ease of maintenance in our designs. Many of our clients have reported that Dekuma’s custom machines require less frequent servicing compared to standard models. This is due to the superior quality of materials used in construction and the careful attention to detail that goes into every machine. With advanced features such as easy-to-disassemble injection pistons, maintenance becomes a breeze, allowing you to minimize downtime and keep production running smoothly.

Conclusion

Choosing between a custom injection molding machine and a standard model is not just about cost—it’s about performance, flexibility, and long-term value. As custom rubber manufacturers, we understand the importance of providing machines that cater specifically to the needs of our clients. By investing in a custom injection molding machine, you can enjoy increased production efficiency, improved precision, and better overall durability. If you’re ready to take your manufacturing to the next level, we are here to help you build the perfect solution tailored to your needs.