At Dekuma, we have been dedicated to developing cutting-edge solutions for the rubber industry since 1997. Our focus on research, production, and sales of liquid silicone rubber injection molding machine has allowed us to provide highly reliable equipment for diverse industries. Over the years, we have refined our technology to meet the unique requirements of sectors such as automotive, power, engineering vehicles, agriculture, and even military applications. By combining our extensive experience with advanced design capabilities, we ensure that our clients can achieve consistent, high-quality production outcomes.

Precision in Niche Applications

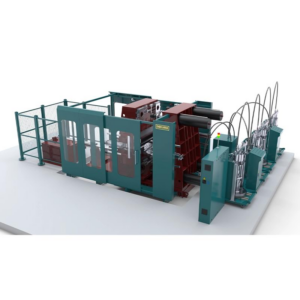

One area where we truly excel is in specialized manufacturing. Our liquid silicone rubber LSR injection molding machine is particularly effective in producing complex components like insulators and rubber tracks, which demand precise tolerances and consistent material properties. By leveraging our in-house design and engineering expertise, we can create machines that adapt to the specific needs of these niche markets. This allows our customers to streamline production processes, reduce material waste, and improve product reliability, which is crucial in sectors where performance and safety cannot be compromised.

Commitment to Material and Component Excellence

At Dekuma, every core component of our machines is designed by our technical team, and we select all raw materials according to rigorous standards. This meticulous approach ensures that our liquid silicone rubber injection molding machine delivers outstanding stability and longevity. Our clients in specialized fields, such as those manufacturing LSR insulators for electrical applications or rubber tracks for construction vehicles, benefit from equipment that maintains consistent performance over long production cycles. The result is higher efficiency, fewer defects, and greater confidence in the quality of the final products.

Custom Solutions and Industry-Focused Innovation

We recognize that every client has unique production requirements. That’s why our liquid silicone rubber LSR injection molding machine is highly customizable, allowing us to provide turnkey solutions tailored to specific industry demands. Whether the need is for high-volume automotive seals or precision rubber components for power systems, our machines can be configured to meet those challenges. By continuously exploring industry-specific opportunities, we ensure that our solutions not only match but often exceed the capabilities of other Chinese manufacturers, offering a competitive alternative to globally recognized brands.

Conclusion

Our mission at Dekuma is to support the development of the rubber and plastics industry through innovation and technology. With our advanced liquid silicone rubber injection molding machine and liquid silicone rubber LSR injection molding machine, we provide clients worldwide with reliable, high-performance equipment tailored to their specialized manufacturing needs. By maintaining our focus on quality, customization, and technical excellence, we help clients achieve better outcomes while contributing to the overall advancement of the industry. We are committed to creating value, driving innovation, and establishing long-term partnerships that benefit our clients, employees, and the broader industrial community.