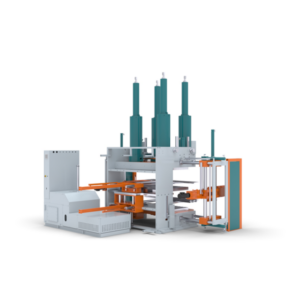

Since our establishment, Dekuma has been committed to delivering high-quality solutions in rubber injection molding. As a company rooted in innovation and practical expertise, we continuously focus on enhancing our machinery to meet the unique needs of various industries. Our experience in the vulcanized rubber molding machine factory sector allows us to provide equipment that is both highly reliable and tailored for specialized production requirements. From automotive components to industrial rubber products, we take pride in supporting our clients with machines that balance precision and efficiency.

Tailored Solutions for Industrial Applications

At Dekuma, we understand that the production of rubber components like insulators and tracks requires specific technical capabilities. Our machines are designed with advanced control systems and durable mechanical components, ensuring consistent performance across large-scale operations. Partnering with leading rubber vulcanizing equipment suppliers, we integrate top-quality materials and precise engineering to guarantee equipment longevity. This approach allows our clients to maintain high production standards while adapting to industry-specific demands, whether in automotive, agricultural machinery, or military vehicle manufacturing.

Innovation in Rubber Track and Specialized Components Manufacturing

One area where Dekuma demonstrates distinct advantages is in the production of rubber tracks and other customized components. Our solutions provide stable temperature control and uniform vulcanization, which are essential for producing high-performance tracks and insulating components. By focusing on specialized applications, we ensure that each machine meets the rigorous demands of industrial manufacturing. Collaborating closely with expert teams enables us to continuously refine our processes, making sure our equipment delivers consistent quality and operational efficiency.

Commitment to Client-Centric Development

We at Dekuma prioritize our clients’ needs in every aspect of machine development. By working directly with rubber vulcanizing equipment suppliers, we can customize equipment layouts, optimize workflow, and integrate technology that enhances usability and reliability. This client-centered approach ensures that each solution not only fulfills immediate production requirements but also supports long-term operational growth. Our dedication to research and development, combined with practical industry experience, allows us to provide machinery that truly adds value to our customers’ businesses.

Conclusion

In the evolving field of rubber manufacturing, Dekuma continues to advance machinery that is precise, reliable, and adaptable. From specialized components such as insulators to complex rubber tracks, our equipment addresses the nuanced challenges of modern production. By leveraging partnerships with expert rubber vulcanizing equipment suppliers and applying our deep experience in the vulcanized rubber molding machine factory sector, we deliver solutions that empower clients to achieve superior results with confidence. Our mission remains clear: to innovate and to provide practical, high-quality rubber molding equipment that meets the specific needs of every industry we serve.