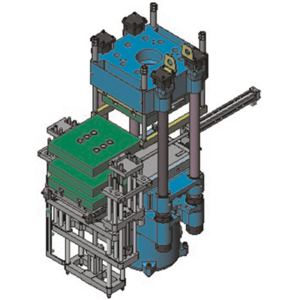

In our continuous journey to support industries that rely on high-quality rubber components, Dekuma has been dedicated to providing reliable solutions for over two decades. We specialize in the development and production of customized rubber molding machines designed to meet the unique needs of our clients. Our machines are widely used in automotive parts, electrical components, and engineering vehicles, where precision and consistency are paramount. By integrating advanced technology with practical design, we ensure our customers achieve efficient production without compromising on quality.

Tailored Solutions for Diverse Applications

We understand that every industry has specific requirements. That’s why our custom molding machines are engineered to adapt to various production scenarios. For instance, in the manufacturing of insulators, our machines offer exceptional control over molding pressure and temperature, ensuring products meet stringent industry standards. Similarly, when producing rubber tracks for construction and agricultural vehicles, our equipment maintains uniform material distribution and dimensional accuracy. This level of adaptability allows us to serve niche markets with specialized machinery, providing our customers with tangible advantages over standard solutions.

Advanced Technology and Component Reliability

At Dekuma, we prioritize the meticulous design and development of core mechanical components, ensuring that all critical parts are engineered in-house by our highly experienced technical team. Every material used in our customized rubber molding machines is carefully and rigorously selected, processed, and inspected according to strict technical and quality standards. This rigorous attention to detail guarantees the consistent reliability, stability, and long-term performance of our equipment, even in highly demanding and continuous production environments. Over the years, our unwavering focus on engineering excellence and precision manufacturing has enabled us to create machines that consistently outperform typical offerings in the market, particularly for specialized industries such as electrical insulator production, heavy-duty rubber track fabrication, and other complex industrial rubber components where precision and durability are critical.

Conclusion

We are committed to providing turnkey solutions that empower our clients to achieve their production goals efficiently. Our custom molding machines are not just pieces of equipment—they represent our dedication to innovation, quality, and industry expertise. By continuously refining our technology and expanding our understanding of specialized markets, we help our clients maximize productivity while maintaining high standards of precision. Looking ahead, Dekuma aims to continue leading in the provision of advanced rubber injection molding solutions, delivering consistent value to our partners and contributing to the growth of the global rubber industry.