In the constantly evolving rubber industry, we at Dekuma are committed to providing innovative solutions that address the diverse needs of our clients. Since 2004, we have specialized in designing and producing high-quality rubber injection molding machines. Our focus on precision, reliability, and tailored solutions ensures that we meet the specific demands of industries ranging from automotive to military applications. By combining advanced technology with years of practical experience, we enable our clients to achieve improved efficiency and product quality in their production lines.

Precision Solutions for Specialized Rubber Products

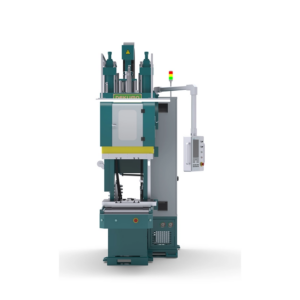

One area where we see significant growth is in the production of insulators and rubber tracks. Our C frame rubber injection moulding machine is particularly well-suited for these applications, offering unparalleled consistency and performance. We designed this machine to handle complex molds and high-viscosity rubber materials, which are critical in manufacturing durable and reliable components. By integrating precise control systems and advanced injection mechanisms, our machines reduce material waste while maintaining tight dimensional tolerances. Clients working with high-performance rubber materials benefit from reduced downtime and enhanced output quality, making our solutions ideal for specialized manufacturing sectors.

Enhancing Versatility with Rubber Sealing Applications

In addition to insulators and rubber tracks, we recognize the growing demand for high-quality sealing products. Our rubber seal making machine is engineered to address the specific requirements of various industrial sealing applications, including automotive, engineering vehicles, and agricultural machinery. We focus on ensuring that each machine delivers consistent results, even when handling challenging rubber compounds. With our expertise, we help clients streamline production processes, minimize defects, and ensure product reliability. The combination of flexibility and precision in our machines allows manufacturers to respond quickly to changing market demands without compromising quality.

Commitment to Innovation and Client Success

At Dekuma, we believe that technology should serve both efficiency and innovation. Every core component of our machines is developed in-house, ensuring maximum reliability and performance. We are constantly exploring opportunities to optimize our designs for niche markets, including electrical insulators and rubber tracks, where specialized equipment can make a substantial difference in production outcomes. Our team is dedicated to providing turnkey solutions, from machine design to technical support, helping our clients achieve measurable improvements in productivity and product quality.

Conclusion

By focusing on the unique challenges of the rubber industry, we at Dekuma provide advanced solutions that go beyond standard manufacturing equipment. Whether it is the C frame rubber injection moulding machine for intricate rubber parts or the rubber seal making machine for specialized seals, our machines are designed to enhance efficiency, precision, and reliability. Through continuous innovation and client-focused development, we strive to empower manufacturers to excel in their respective markets while maintaining high standards of quality and performance.