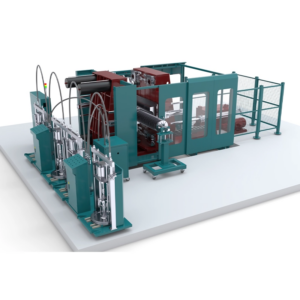

The need for better-quality rubber components is growing along with industries. These demands have been met by Dekuma’s rubber injection molding machine technology, particularly in sectors like electronics, vehicle parts, and baby care items. Our injection molding equipment is the best option for companies looking to improve their manufacturing procedures and meet the increasing needs of the market since it combines efficiency, precision, and adaptability.

Achieving Precision with Synchronized Dosing

One of the key advantages of our rubber molding machines is the patented synchronized dosing device. This cutting-edge technology ensures that the injection volume is always accurate, providing manufacturers with a high level of control over the molding process. The synchronized dosing system is adaptable to the specific requirements of the product being produced, allowing for precision in every shot. This feature is particularly beneficial for industries like electronics and automotive manufacturing, where precision is essential for creating functional and durable components. Whether it’s producing tiny components for consumer electronics or large parts for automotive applications, this technology ensures consistency and reliability across various production runs.

Reducing Operational Costs with Energy Efficiency

In an era where energy costs and environmental impact are major concerns, Dekuma’s Liquid Silicone rubber injection molding machine is engineered to reduce operational expenses. Manufacturers who adopt our energy-saving technology can achieve significant savings in energy costs while contributing to more sustainable production practices. With this reduction in power consumption, businesses can reinvest the savings into other areas of their operations, further optimizing their overall production processes.

Ensuring Reliability Across Diverse Applications

Dekuma’s rubber molding machines are designed to operate seamlessly across various industries, ensuring versatility in every application. From manufacturing insulators and arresters for the electrical industry to producing food-safe containers and sports equipment, our machines are built to handle a wide range of materials and production needs. The high-precision static mixer ensures an even and thorough blend of materials, which is critical for industries that require uniformity in their product output. Whether the application demands strict safety standards, like those in the food or medical sectors, or the durability needed for automotive parts, Dekuma’s machines are capable of meeting the highest production standards.

Conclusion

In the rubber molding sector, Dekuma‘s injection molding equipment leads the way with creative solutions that help companies save money, increase productivity, and achieve accuracy. Because of our technology’s versatility and dependability, manufacturers in a wide range of industries, including electronics, automotive, and baby care, can produce high-quality rubber components that satisfy their clients’ needs. With their versatility, Dekuma’s machines not only aid in streamlining production procedures but also guarantee that your goods constantly fulfill the highest requirements for performance and quality.