Unlike other elastomers, Liquid Silicone Rubber requires a unique set of process parameters for production. At Dekuma, we are well-versed in these subtleties. Our method for developing an LSR injection molding machine is based on controlling the material’s two-component properties from the time it enters the system. Those in the manufacturing industry who require the exact execution of complicated recipes can rely on this LSR injection molding machine, which is tailored to the unique rheology and curing behavior of LSR.

Managing Material with Accurate Dosing

The initial stage of the process is critical for the entire production cycle. Our liquid silicone rubber injection molding machine uses a patented synchronized dosing system. This technology allows for the consistent measurement of both material components. The system also permits easy adjustment of these ratios to suit different product sizes and weights. This level of control is a fundamental feature for any modern LSR injection molding machine, as it directly influences the chemical integrity of the final cured part. It provides the flexibility needed for short runs and custom orders without compromising on the repeatability required for larger production volumes.

The Importance of Uniform Blending in LSR

After dosing, achieving a perfectly homogeneous mixture is the next vital step. Our LSR injection molding machine is fitted with a high-quality static mixer. This component is engineered for high precision, ensuring that material A and material B are blended into a uniform compound before entering the injection unit. The consistency of this mixing action is a key factor for any liquid silicone rubber injection molding machine. It guarantees that the cross-linking reaction proceeds evenly throughout the entire shot, which is essential for producing parts with uniform physical properties, clarity, and color.

Integrating Systems for Dependable Output

The combination of precise dosing and consistent mixing establishes a reliable process foundation. When these two systems work in unison, the variability inherent in two-component materials is significantly reduced. This integration allows our LSR injection molding machine to produce parts with a high degree of consistency from the first shot to the last. For a manufacturer, the performance of their LSR injection molding machine is measured by its ability to minimize waste and ensure that every part meets specification. This operational reliability is what makes the Dekuma system a practical choice for medical, automotive, and consumer goods applications.

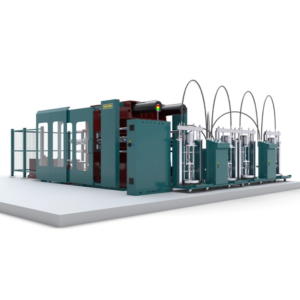

If you work with liquid silicone rubber, Dekuma has you covered with their RT Series. Our dedication to mastering the unique physics of working with materials that consist of two distinct components led us to develop this LSR injection molding machine. All of the design decisions, including the static mixer and dosing system, are based on what is actually happening on the manufacturing floor. For materials that require precise control, our Dekuma China LSR injection molding machine provides a reliable and reproducible procedure.