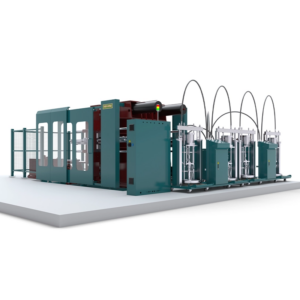

The Dekuma RI Series stands out as the best option for rubber injection molding equipment that combine affordability and excellent performance. The RI Series is a reliable option for manufacturing rubber goods, general insulators, and other applications requiring accuracy and dependability. It was designed with simplicity and practicality in mind. Manufacturers looking for an effective machine that is simple to use provides long-term value, and satisfies high production standards will find the RI Series particularly appropriate. Dekuma’s RI Series is designed for companies that require a dependable solution without needless complication by emphasizing efficiency and simplicity.

Simple Operation with Dual-Seal Clamping Cylinder

One of the key features of the RI Series is its straightforward hydraulic cylinder feeding system. This design ensures that the machine is simple to operate while maintaining high precision during production. The dual-seal clamping cylinder design is another standout feature, which significantly prevents oil leakage and contributes tomore stable and durable rubber injection molding equipment. The dual-seal system not only enhances the reliability of the machine during extended operations but also reduces the potential for costly downtime and maintenance. As a result, this system helps keep your operations running smoothly with minimal maintenance needs over the long term, ensuring a lower total cost of ownership.

Flexible Operation with Double Station Option

The RI Series also offers flexibility through its double station option, which is especially useful for businesses aiming to maximize production efficiency. With this option, two molds can be cycled simultaneously, effectively doubling the output and improving throughput. This makes the RI Series rubber injection moulding machine an ideal solution for manufacturers involved in high-volume production runs. Whether you are producing large quantities of standard rubber products or working on projects that require frequent mold changes, this double-station option helps you meet your production goals more efficiently.

Precision and Long-Term Durability

For precision and long-term durability, the RI Series uses German hydraulic valves, which provide smooth and accurate operation throughout the machine’s service life. The valves ensure that the machine consistently operates at a high level of precision, producing parts with minimal variability and maximum quality. Additionally, the Siemens control system incorporated into the RI Series offers a user-friendly interface, making it easier for operators to monitor and adjust settings for optimal performance. The control system enhances ease of operation, allowing users to fine-tune the machine’s performance quickly and intuitively.

Conclusion

An affordable, high-performing choice for enterprises looking for a dependable way to produce general rubber goods is the RI Series rubber injection molding machine. The RI Series is an excellent option for businesses wishing to maximize their rubber molding operations because of its straightforward operation, adaptability, and sturdy build. The Dekuma RI Series provides the value and dependability required to thrive in the cutthroat manufacturing world of today, whether your goal is to increase production efficiency or lower maintenance expenses.