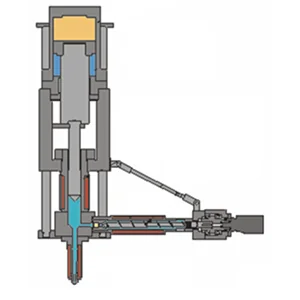

Guide to LSR Injection Molding Process and Machine

Liquid Silicone Rubber (LSR) is a durable and flexible material known for its resistance to heat, chemicals, and harsh environments. The LSR injection molding process converts this material into durable, high-precision products. It involves injecting the material into molds under controlled heat and pressure, allowing rapid curing and minimal waste. Common applications include automotive seals, […]

3 Best Rubber Injection Molding Machine Manufacturers

Rubber injection molding machines function to create precise, durable parts through pressure-driven molten rubber injection into molds. The manufacturing process serves multiple industries that need high-precision parts, including the automotive, medical, and electronics sectors. The following article presents three top injection molding machine manufacturers, which will assist you in selecting your ideal production partner. […]

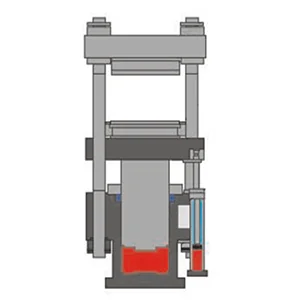

What Role Does a Rubber Vulcanizing Machine Play in Manufacturing?

Rubber vulcanizing machines are critical equipment in the rubber manufacturing process, widely used for producing durable and high-performance rubber products. At Dekuma, we specialize in rubber vulcanizing equipment designed to meet the growing needs of various industries. Whether it’s agricultural tracks, construction vehicles, military machinery, or snowmobiles, Dekuma offers state-of-the-art vulcanizing machines that improve efficiency […]

Custom Injection Molding Machine: Unlocking Greater Efficiency Compared to Standard Models

In today’s competitive manufacturing landscape, choosing the right machinery can make a huge difference in the efficiency, precision, and overall output of production. For companies looking to produce custom rubber parts, a custom injection molding machine could be the key to unlocking enhanced performance. At Dekuma, we specialize in creating tailor-made machines that cater to the […]

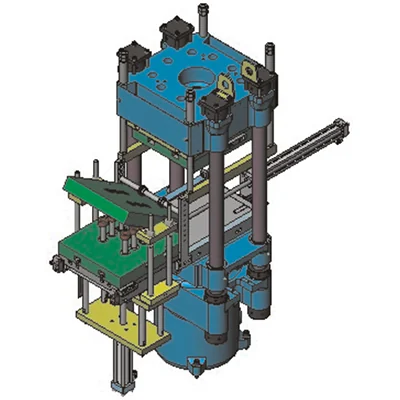

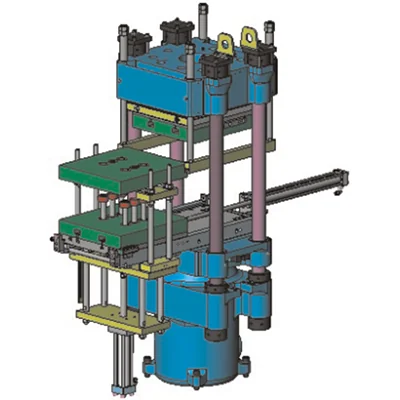

How to Optimize Floor Space Efficiency with Customized Injection Molding Machines

At Dekuma, we understand the importance of maximizing floor space efficiency, especially in a competitive manufacturing environment. Our team of experts works tirelessly to design customized injection molding machines that not only meet your production needs but also save valuable space in your facility. Manufacturers today are constantly looking for ways to enhance productivity while […]

Understanding Rubber Molding Processes: A Guide to Custom Solutions

At Dekuma, we specialize in providing custom molding machines tailored to meet the specific needs of our clients. Whether you’re a manufacturer looking for the best production solutions or you’re exploring different types of rubber molding processes, we’re here to help. With the expertise of custom rubber manufacturers like us, we ensure that every molding machine […]

The Role of PLC in Injection Molding and How Dekuma Optimizes It

Injection molding is a highly efficient and versatile manufacturing process, but for it to function at its best, advanced control systems are essential. One of the most significant control systems used in modern injection molding machines is the Programmable Logic Controller (PLC). PLCs play a crucial role in streamlining operations, increasing precision, and enhancing the […]

The Future of Injection Molding: Advancements and Trends

The world of injection molding is constantly evolving, driven by technological advancements and the demand for more customized solutions. As industries continue to push the boundaries of what’s possible, injection molding processes are becoming more efficient, precise, and versatile. At Dekuma, we are proud to be part of this innovation, working alongside custom rubber manufacturers and […]

Different Methods for Rubber Molding and Why It Matters for Custom Manufacturers

Rubber molding is a critical process for manufacturers in a wide range of industries. Understanding the various molding techniques available is essential for ensuring the quality and precision of rubber parts. At Dekuma, we specialize in creating custom solutions for customers in need of rubber molded products. As one of the prominent custom rubber manufacturers, […]

Custom Rubber Moulded Products vs. Other Manufacturing Options: A Comprehensive Guide

When it comes to manufacturing specialized components, industries often face the decision of choosing between custom rubber moulded products and alternative manufacturing methods. At Dekuma, we have extensive experience in delivering customized rubber solutions to meet various production needs. Understanding the differences between custom rubber moulding and alternatives such as plastic injection moulding, die-casting, or […]