Compression vs. Injection Molding for Rubber: Key Differences Explained

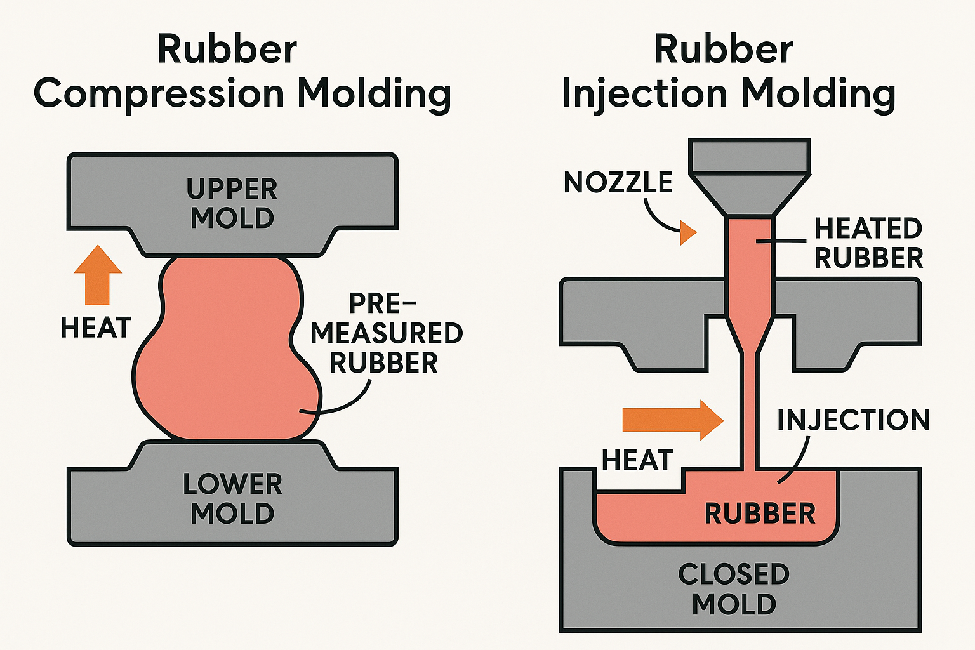

Rubber parts usually start as soft, hot material. In compression molding, you press a pre‑measured chunk between heated dies and let it cure. It’s simple and great for thick or low‑volume parts. Injection molding pushes heated rubber through a nozzle into a closed mold, filling every corner fast. That method handles complex shapes and higher production […]